The Salt Miner:

How It Works

What does The Salt Miner DO?

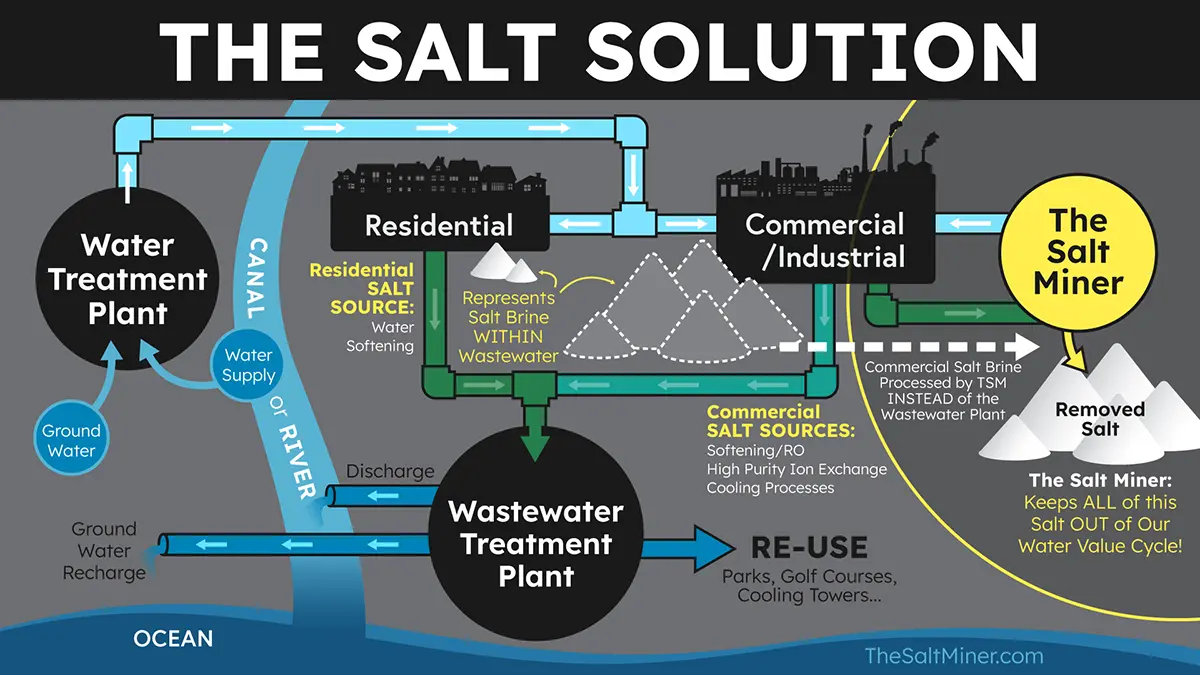

The Salt Miner extracts (“mines”) salt from brine generated by water treatment processes, such as water softening and cooling tower blowdown directly at the source BEFORE it is discharged to wastewater & sewer systems.

By removing salt pollution from a major point source, The Salt Miner not only mitigates environmental concerns related to salt contamination but also facilitates on-site water recycling, contributing to sustainable and cost-effective water management practices. This groundbreaking solution ensures that the benefits of water treatment are retained while significantly reducing the negative impact of salt on water quality and ecosystems.

The treatment of water to make it useable for industry is adding BILLIONS of pounds of salt into our wastewater.

The Salt Miner would sit between the brine source and drain pipe to prevent this salt from entering the water value cycle.

How The Salt Miner Removes Salt

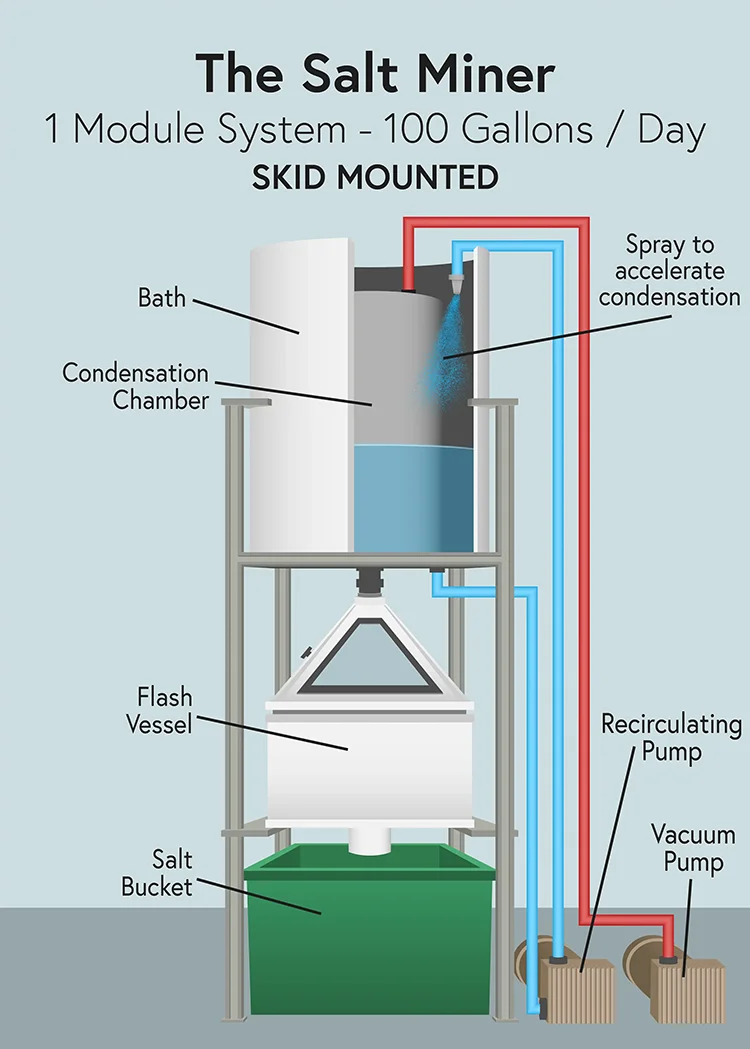

- The Salt Miner sits between the brine source & the drain.

- The brine goes into “the flash vessel”.

- A vacuum is created to lower the boiling point.

- Standard 120 AC electrical current is passed through the brine – the higher the salinity level the more conductive the brine optimizing efficiency.

- Heat is added causing the water to vaporize “out of the brine”.

- The steam rises and is collected as low TDS water in the “condensation chamber”.

- The condensation chamber is surrounded by a “bath” of good water that is re-circulated & sprayed on the condensation chamber to cool it thus accelerating the process & lowering operational costs.

- When the batch is fully treated the system shuts off & the good water is discharged or re-used & the salt is collected in the “salt bucket”.

- The salt bucket is emptied as needed for disposal or recycling.

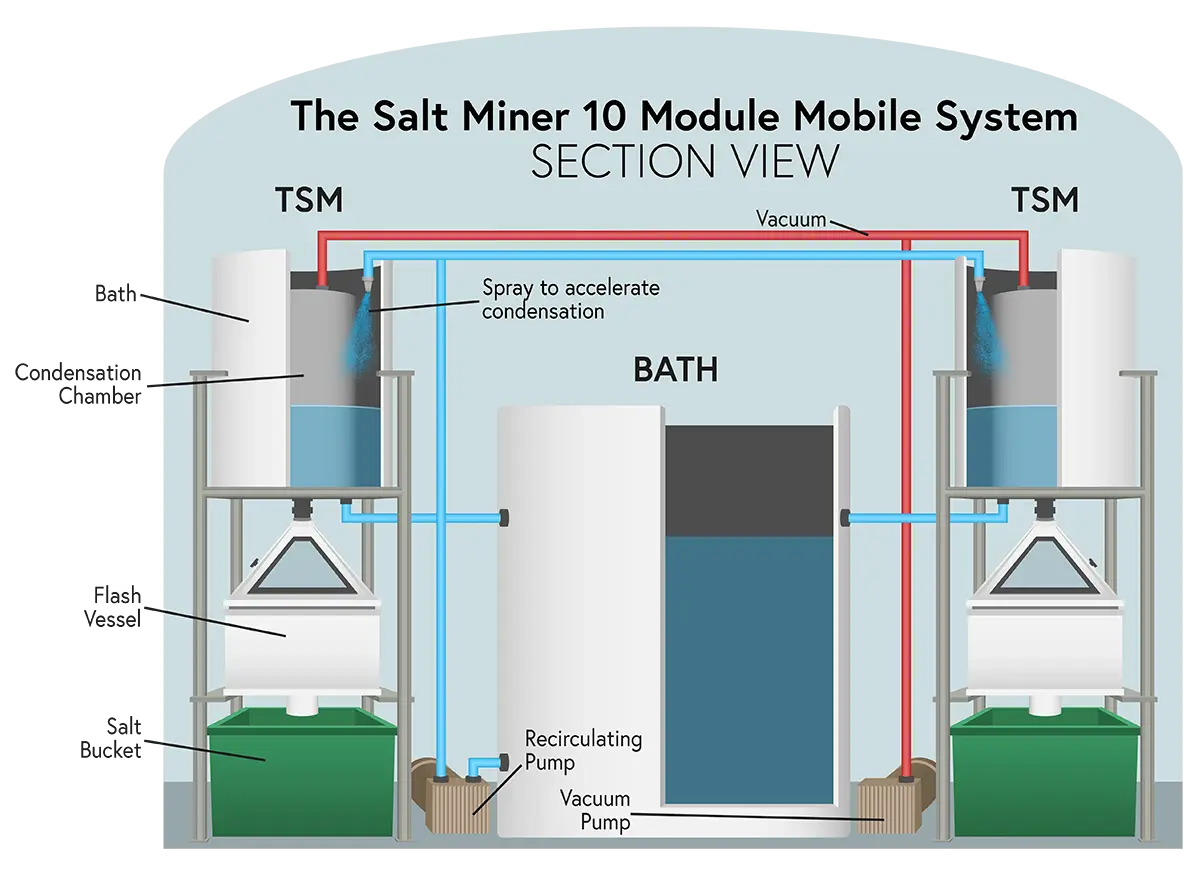

Multi-Module System for

High Volume, Industrial Use

The Salt Miner excels in large-scale applications, efficiently removing salt from industrial wastewater streams, providing a scalable solution for diverse industries seeking sustainable water management and reduced environmental impact.

Test Results for Recycling Cooling Tower Blowdown

The Salt Miner’s Impactful Performance

The Salt Miner, a key player in a team awarded a Bureau of Reclamation grant, showcased its effectiveness in recycling cooling tower blowdown through a comprehensive treatment train. The project involved several stages:

Pretreatment

Removal of excess hardness and debris.

Low-Pressure RO (Reverse Osmosis)

Recovery of most of the water.

The Salt Miner

Treatment of the brine from the RO system.

Project Highlights:

- Cooling tower blowdown, initially at ~2,600 ppm TDS, was captured in a kiddie swimming pool.

- After pretreatment and a 3-pass RO, the concentrate reached ~16,000 ppm TD.

- The brine was then transferred to The Salt Miner for further treatment.

- The Salt Miner exhibited enhanced performance at higher TDS, with a “spiked” brine reaching 50,000 ppm.

- TDS levels continued to rise as water evaporated, ultimately surpassing 183,000 ppm.

Results and Conclusions:

- Throughput exceeded the target by 20%, with ongoing improvements post-project.

- The TDS of the distillate was an impressive 70% lower than the target.

- The Salt Miner operated at 130 degrees F under a 21-22” Hg vacuum.

- Anticipated system optimization is expected to double the throughput achieved during the project.

Endorsement by Dr. Mike Mickley

Dr. Mickley served as a special advisor to the principal investigator on the Bureau of Reclamation funded cooling tower blowdown recycle project. After analyzing the Pitch-to-Pilot results Dr. Mike Mickley said this about The Salt Miner’s performance:

- Has demonstrated “Proof of Concept”

- Is unique – Flooding brine with electrons under vacuum creating ohmic heating has not been done before

- Looks to be a good option for dealing with high-strength brines – TSM is the only idea that works better as the brine gets saltier

- Is ready for product development & optimization to refine costs and operating parameters

About Dr. Mike Mickley

Dr. Mike Mickley is a recognized expert on desalination and brine management in water treatment. He has studied and worked extensively, received a number of grants for work in the field and published a number of articles on the topic. He is a frequent contributor to commercial publications and speaker at conferences as well as advising new companies and investors in this area.

View Online Resume